Latest Article

-

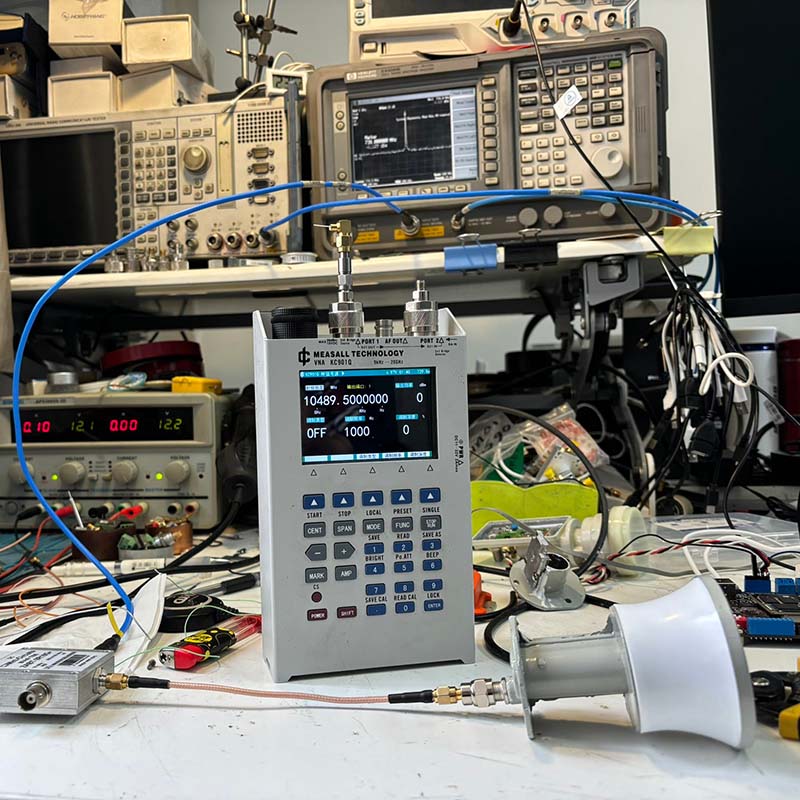

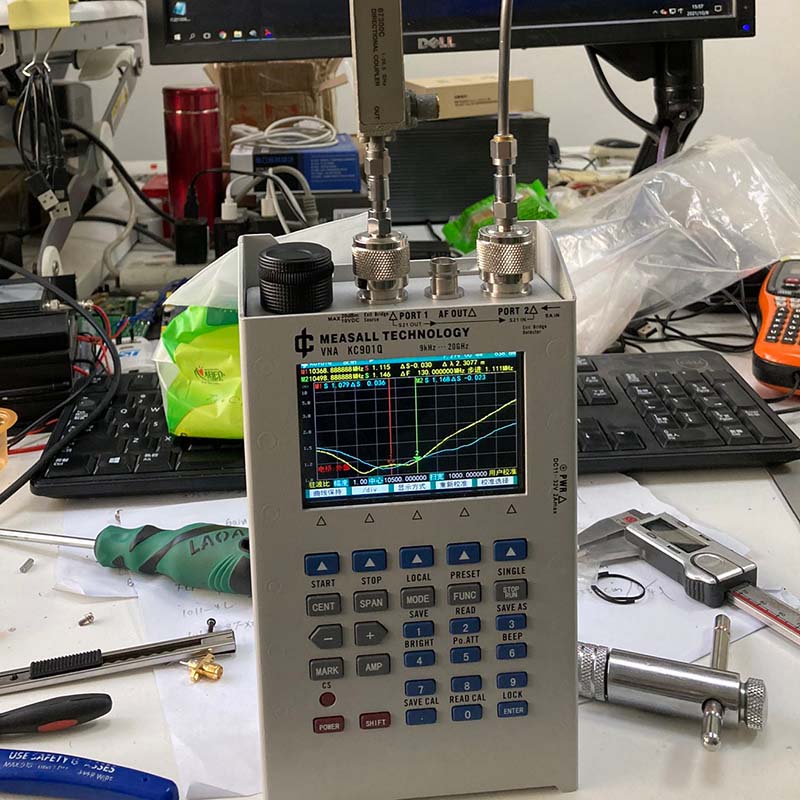

Tutorial for KC901Q Measuring Reflective Parameter S11

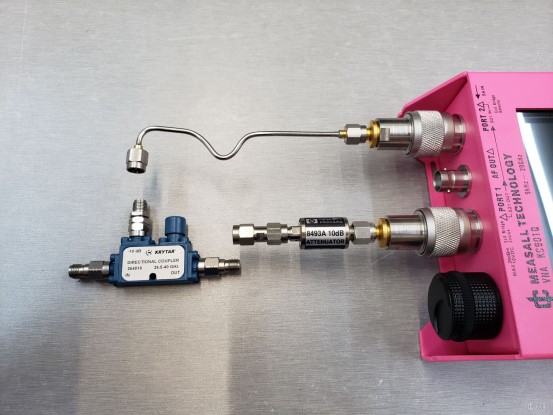

KC901Q is a RF multimeter without built-in directional components. The main reason of the absence of bridge and directional coupler is the fact tha...

-

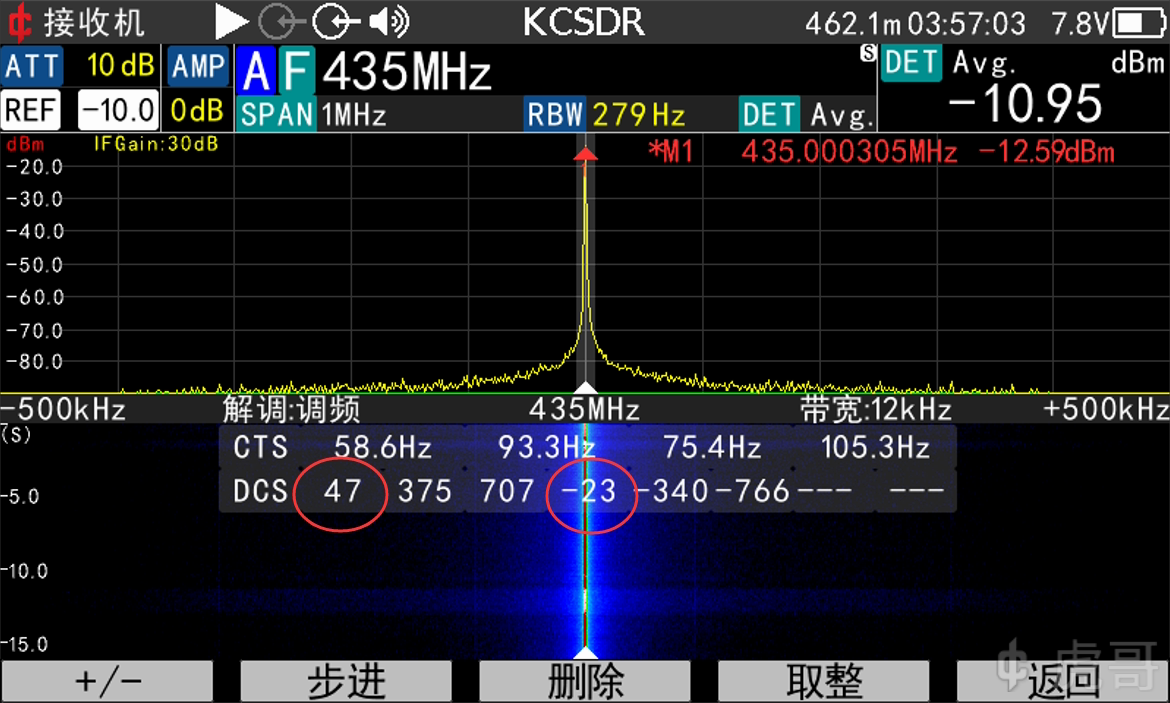

Some knowledge about DCS Digital Tone Squelch Analysis (Decoding)

Continuous Digital Controlled Squelch System (CDCSS), also known as Digital Coded Squelch (DCS), is a commonly used squelch or call selection metho...

-

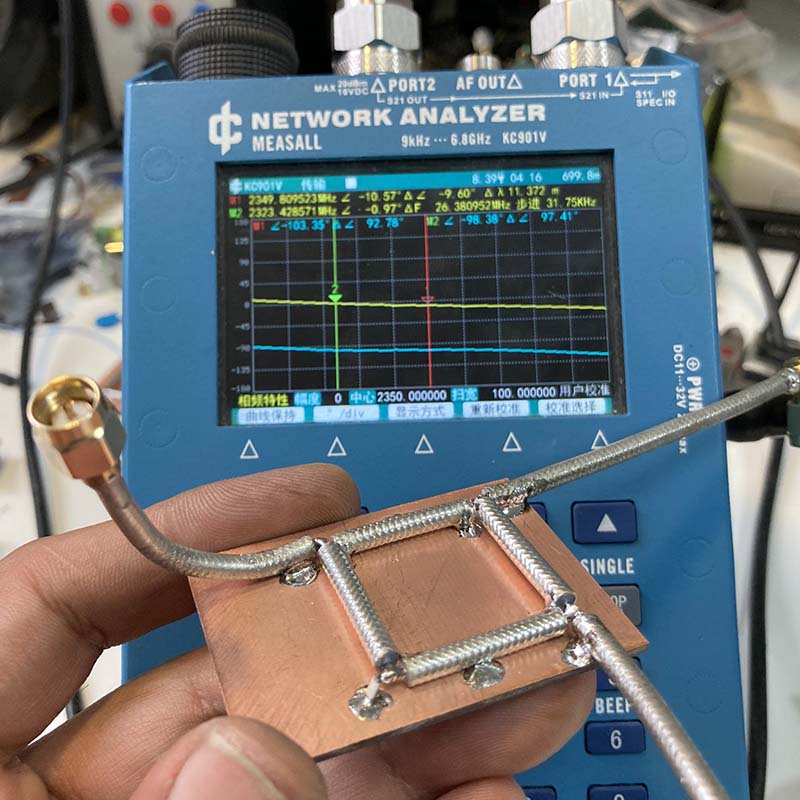

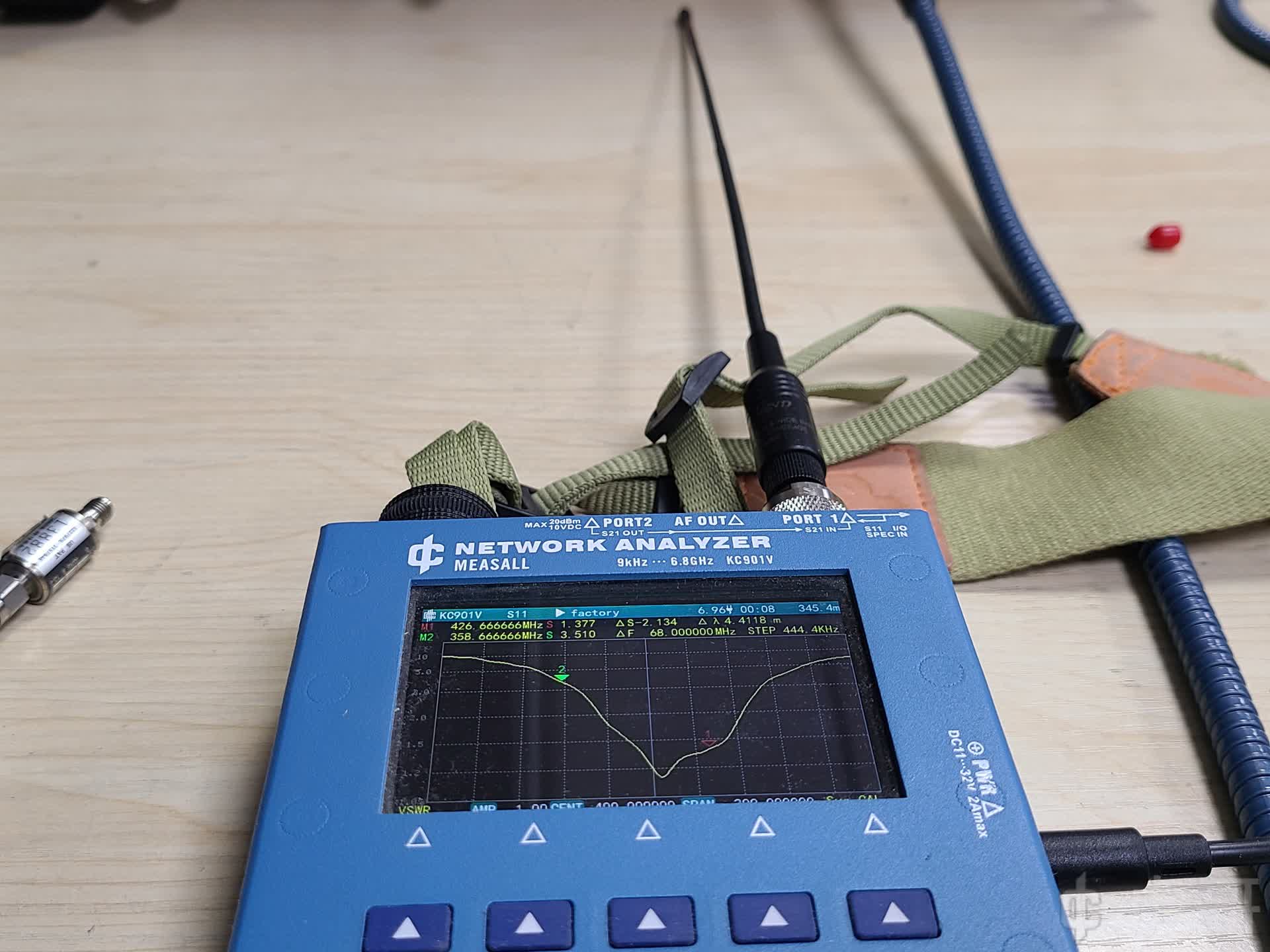

Learning from whip antenna VSWR/resonance point testing

Portable antenna analyzer has been rapidly popularized in recent years, which brings great convenience for testing. However, people pay little atte...

-

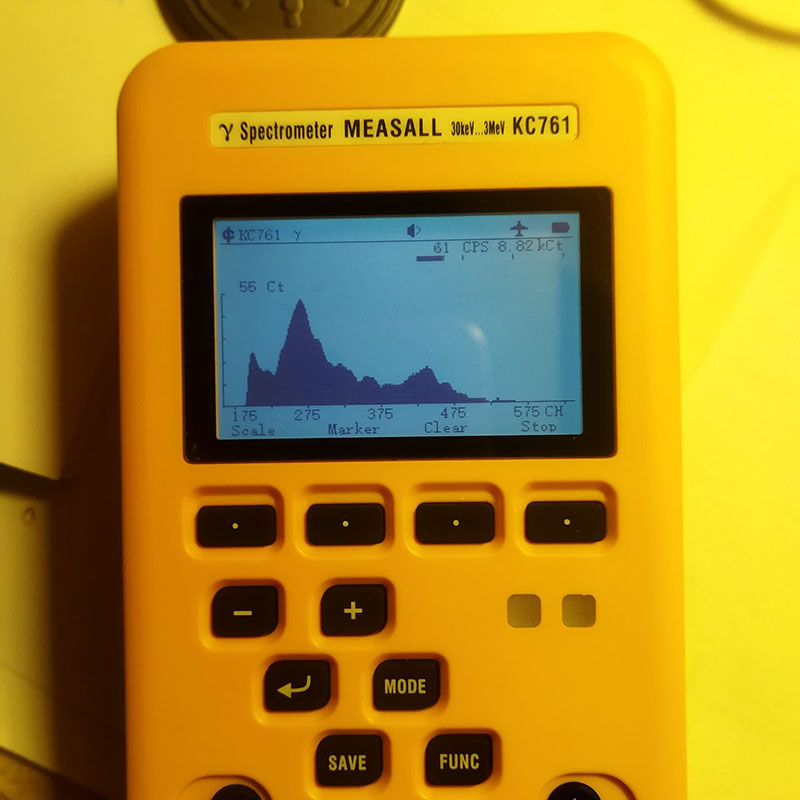

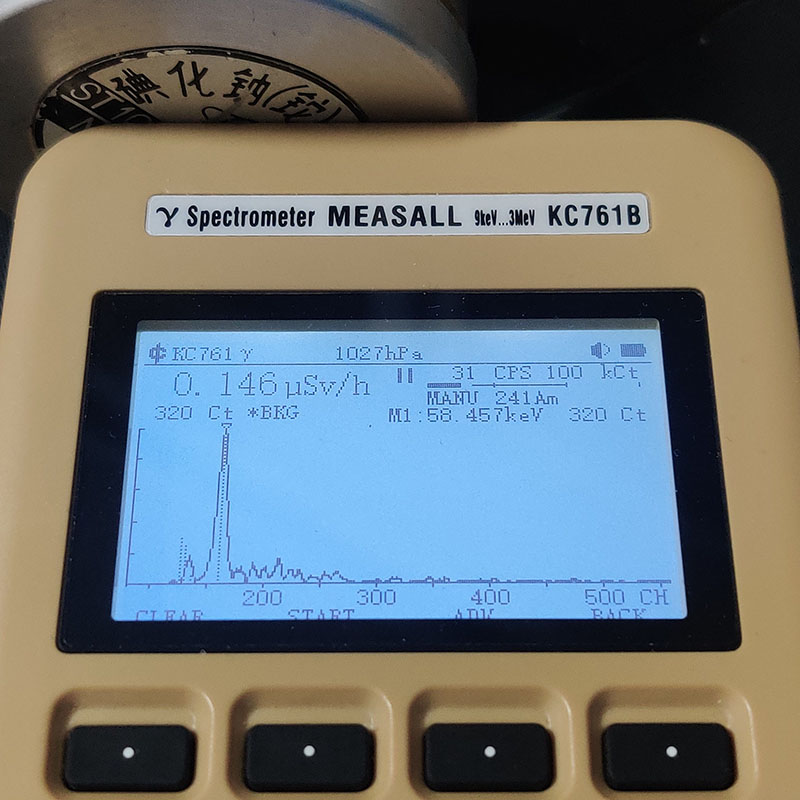

KC761 User Energy Correction

The KC761 uses a complex temperature compensation algorithm to compensate for temperature-induced drift with good results. However, the coupling be...

-

KC901* firmware update guide

The KC901 has an upgrade function, you only need to save the ROM package you downloaded from the Internet to your TF (micro SD) card, follow these ...

Explore Videos

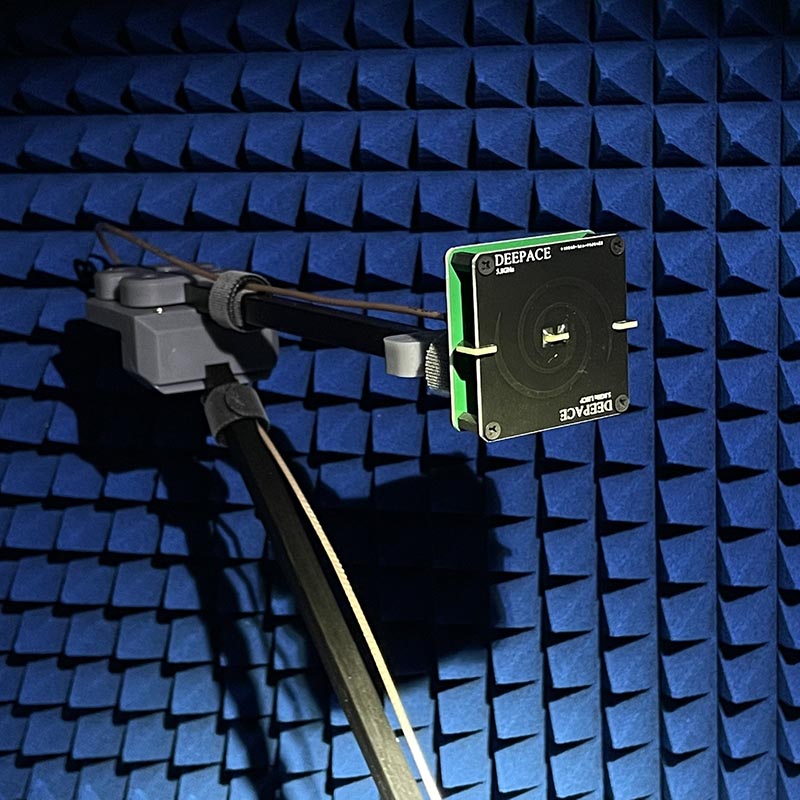

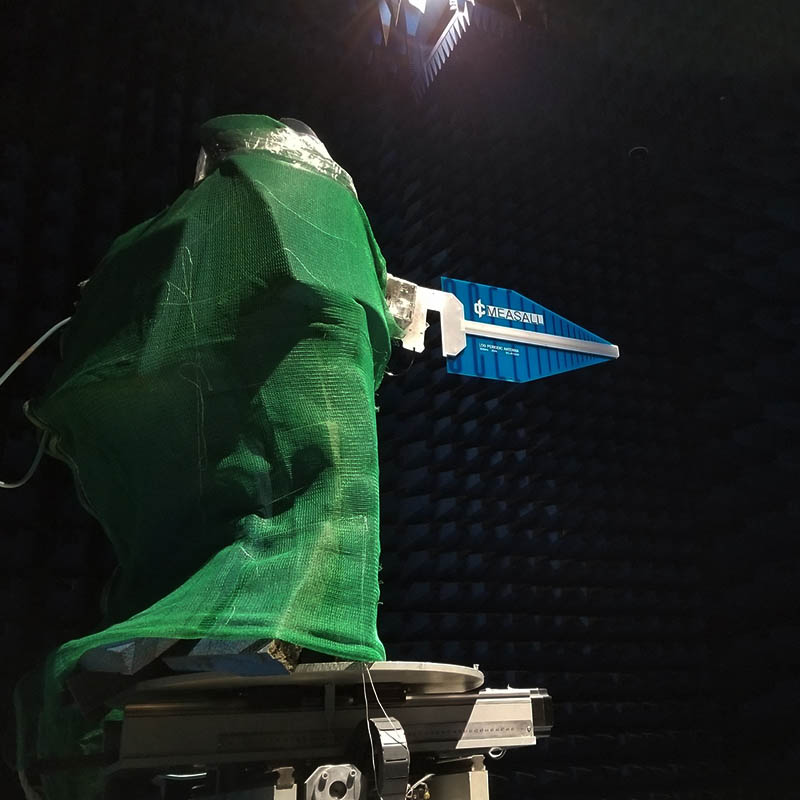

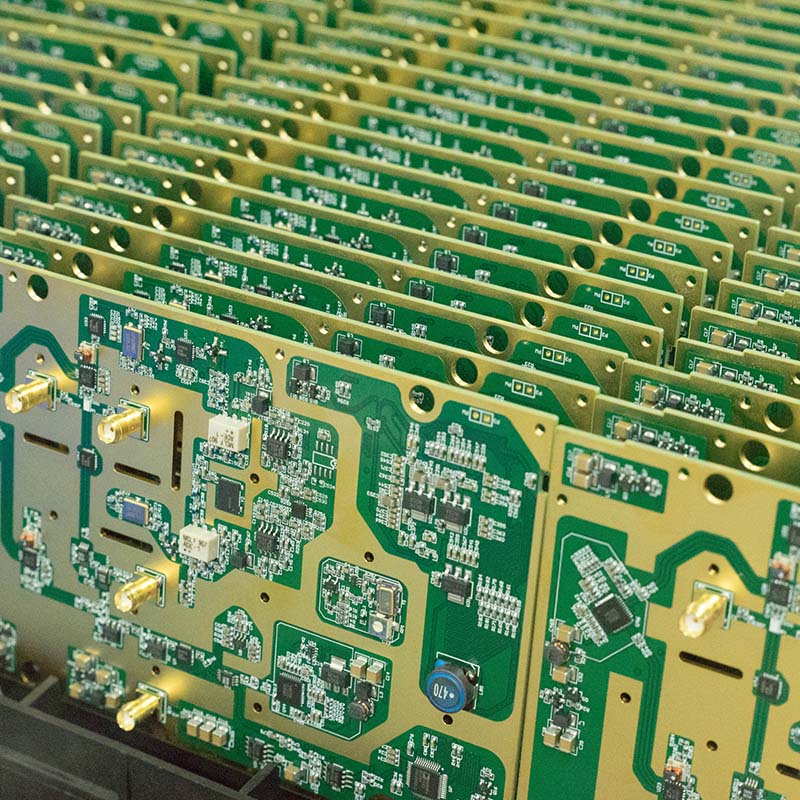

Browse Deepace Gallery